Pig Tracking: Enhancing Pipeline Safety and Efficiency with Real-Time Monitoring

When it comes to pipeline pigging operations, precision, safety, and efficiency aren’t just goals—they’re essential. At N2 Solutions, we take...

2 min read

N2 Solutions

:

May 22, 2025 10:06:31 AM

N2 Solutions

:

May 22, 2025 10:06:31 AM

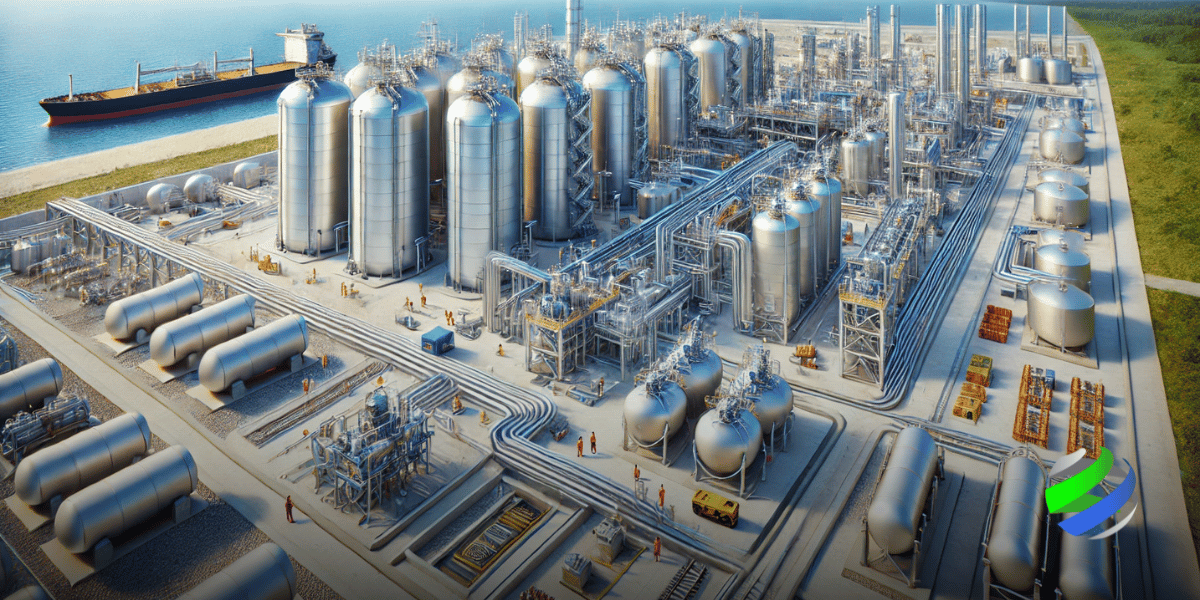

When it comes to industrial pipeline services, safety, reliability, and performance aren’t just priorities — they’re non-negotiable. At N2 Solutions, we go beyond nitrogen pumping to deliver customized, high-performance solutions built on a foundation of safety excellence.

At N2 Solutions, pipeline safety isn’t just a priority—it’s a core value. Our commitment to safety best practices drives every project we take on. In this article, we’ll break down how we set the standard for pipeline safety by focusing on:

At N2 Solutions, safety isn’t just about checking boxes — it’s a deeply embedded mindset and the backbone of every jobsite. We’ve proudly maintained a 0.00 Total Recordable Incident Rate (TRIR) for three consecutive years, proving that zero-incident pipeline operations are possible with the right systems and culture in place.

This isn’t luck — it’s the result of a deliberate and strategic safety culture in the oil and gas industry, proven effective in complex field environments like nitrogen purging at an LNG facility.

While others rely on post-incident reviews, N2 Solutions uses a system of real-time hazard identification to flag and resolve risks before they escalate. N2's corrective action tracking system closes the loop, ensuring accountability across teams.

On-site audits with digital reporting tools

Immediate risk flagging and alerting

Verified closure of all corrective actions

This proactive approach minimizes downtime and protects both personnel and assets — reinforcing the importance of pipeline cleaning and inspection best practices as part of a broader safety strategy.

One of the biggest weaknesses in many pipeline operations is inconsistency. N2 combats this with rigorous field audits and compliance verification.

Structured site audits are conducted

Digital documentation and follow-up tracking

Transparent data that informs monthly safety reviews

This consistency is a cornerstone of their broader Health, Safety, and Environmental Management System (HSEMS), which ensures accountability from the field level to executive leadership, much like the standardized practices in N2’s freeze plugs.

Accidents don’t wait — and neither does N2. With advanced emergency response planning, crews are trained to handle critical situations with speed and precision.

Preparedness isn't an afterthought — it's embedded in project startup, field training, and operational SOPs. This level of planning and readiness is akin to their commitment to environmental and emergency planning seen in their ESG initiatives.

What gets measured gets improved. N2 uses safety KPIs to ensure performance isn’t just maintained — it’s constantly optimized.

Their KPI system monitors:

TRIR and near-miss reports

Root cause analyses of incidents

Corrective action closure timelines

Safety training completion and audit adherence

This commitment to data-driven safety improvements fosters a transparent, high-performing culture, much like the data-driven approach in their digital reporting tools that optimize safety outcomes.

Choosing a pipeline services partner isn’t just about speed or pricing — it’s about protecting your team, assets, and bottom line. N2 Solutions doesn’t just comply with safety standards — they exceed them.

Fewer incidents

Reduced project downtime

Stronger long-term ROI for every project.

%20(3).png?width=180&height=90&name=N2%20-(300%20x%20150)%20(3).png) N2 Solutions strengthens its position as a nitrogen services leader with the acquisition of PFS Nitrogen Services, expanding its locations and product offerings. With pump trucks, nitrogen transports, pig tracking, and pipe freeze technology, N2 delivers cost-effective solutions to energy, industrial, chemical, and pipeline clients. N2 Solutions sets a new standard of excellence in nitrogen solutions for its customers.

N2 Solutions strengthens its position as a nitrogen services leader with the acquisition of PFS Nitrogen Services, expanding its locations and product offerings. With pump trucks, nitrogen transports, pig tracking, and pipe freeze technology, N2 delivers cost-effective solutions to energy, industrial, chemical, and pipeline clients. N2 Solutions sets a new standard of excellence in nitrogen solutions for its customers.

When it comes to pipeline pigging operations, precision, safety, and efficiency aren’t just goals—they’re essential. At N2 Solutions, we take...

Get ready, Houston! From June 11-12, 2025, N2 Solutions will be at the Energy Projects Conference & Expo, discussing our nitrogen services at Booth...

Safety is at the core of LNG operations, and N2 Solutions is committed to ensuring the highest standards through innovative nitrogen services and...