What Is Pigging? A Comprehensive Guide to Pipeline Cleaning and Safety

In the pipeline industry, maintaining the cleanliness and integrity of pipelines is crucial for ensuring safe and efficient operations. One of the...

4 min read

N2 Solutions

:

Nov 6, 2025 11:00:00 AM

N2 Solutions

:

Nov 6, 2025 11:00:00 AM

Transmission pipelines have become integral systems worldwide, enabling the safe transportation of essential energy products over long distances, including natural gas, crude oil, and methane. Millions of miles of pipelines operating across these vast networks must be rigorously maintained, regularly cleaned, and inspected to ensure system integrity. As these operational demands increase amidst rising energy consumption and urban growth, pipeline networks are operating at higher capacities than ever before. To safeguard these routine and high-stakes operations, advanced cleaning technologies have become a critical practice to bolster productivity.

This article covers three key reasons for pipeline cleaning: improving efficiency, ensuring successful in-line inspections, and preparing for hydrostatic testing. We then explore the key features of N2 Solutions' online and offline chemical cleaning service line. N2 Solutions has deep roots in the midstream pipeline sector through well-established services such as nitrogen purging and pipe freezing. This service line is the culmination of years of relentless efforts to support pipeline readiness, maximize flow efficiency, and safeguard long-term asset integrity throughout the pipeline life cycle.

Pipeline systems transport a range of products that vary in composition and abrasiveness. While aggressive products like crude oil result in byproducts that accumulate in the line and must be treated and removed, even clean gas products are accompanied by lubricants, flow promoters, and corrosion inhibitors that build up inside the line over time, reducing productivity. Common contaminants that accumulate in pipelines include paraffin waxes, scale, compressor oils, and black powder, among others.

There are numerous reasons that pipelines must undergo thorough cleaning, some of which are explored below.

Pipeline contaminants present several problems for pipeline operators. Firstly, buildup and excess debris present in a line reduce its internal diameter and create a rougher surface. This both increases friction and restricts the flow of product, meaning more energy and higher pressures are needed to transport the same volume. Even a 5% buildup in the cross-sectional area can decrease throughput by as much as 35%. To overcome the increased friction and maintain the desired flow rates, pumps and compressors must work harder, leading to significantly higher energy consumption and operational costs. Additionally, deposits can trap moisture and corrosive agents against the pipe wall, creating localized areas of accelerated corrosion that can compromise the pipeline's integrity over time. A rigorous pipeline cleaning schedule removes buildup present in the line, safeguarding overall throughput. This reduces overall energy costs and ensures a longer, more productive lifespan for the pipeline asset.

A debris-heavy pipeline can disrupt the accuracy of inspection tools during in-line inspections (ILI). An accurate ILI run requires close contact with the pipe wall. When debris on the pipe wall prevents an ILI tool’s sensors from directly contacting the pipe wall, sensor liftoff occurs. Sensor liftoff interferes with accurate data collection, leading to incomplete or inaccurate readings. Furthermore, hard scale or other debris can damage the sensitive instruments contained on the ILI tool. Significant accumulations of debris can obstruct the path of the ILI tool, potentially causing it to become stuck. A failed ILI run due to a dirty pipeline or a stuck tool is a significant financial setback, potentially requiring costly re-runs and operational delays. Thoroughly cleaning a pipeline beforehand minimizes these costly risks. Therefore, a thorough cleaning program is an essential prerequisite for any ILI campaign.

Following hydrostatic testing, large volumes of water must be discharged into the ground. However, this water must meet stringent environmental regulations to prevent contamination of soil and water resources. Before discharge, the operator must demonstrate that the disposed water will be clean. To meet these requirements, pipelines are cleaned before the hydrostatic test begins to remove as much debris as possible. By cleaning the pipeline beforehand, the water used for the hydrostatic test itself remains much cleaner, making it easier and less costly to treat before discharge. This proactive step is crucial for environmental protection and regulatory adherence.

To successfully safeguard pipeline productivity, facilitate successful ILI runs, and enable safe post-hydrotesting surface discharge, pipeline operators turn to chemical cleaning practices. Chemical cleaning integrates mechanical pigging with liquid cleaning agents formulated to dissolve, suspend, and remove debris. These solutions permeate deposits, break down chemical bonds, and enable the complete removal of harmful debris from the pipeline system. Chemical cleaning can be enacted in one of two protocols: online cleaning or offline cleaning.

This method enables a complete pipeline cleaning regimen to be implemented while the pipeline remains operational, a practice that maximizes uptime for the operator. Cleaning chemicals are injected inside the pipeline ahead of a customized pig and propelled through the system along with the product. Upon run completion, excess liquids and solids are isolated from the line via a separator and deposited into a frac tank, while the product continues uninterrupted through the system.

Offline cleaning is performed during a scheduled shutdown of the pipeline. Cleaning chemicals are again injected ahead of the pig and propelled through the line, but do not need to be “separated” from the existing product flow because the line is not operational. While this method increases downtime, it can effectively facilitate a multitude of needed maintenance activities if a shutdown is already planned or underway.

To broaden support and provide enhanced value for pipeline operators, N2 Solutions offers a range of specialized cleaning chemicals, do-it yourself cleaning programs, and 24/7 chemical engineering support, available for both online and offline applications. N2 Solutions delivers leading-edge chemical cleaning products that can be custom-formulated to meet the specific needs of pipeline operators. With lab analysis, pipeline operators provide a unique sample of the debris present in their pipeline and receive an expert-formulated chemical cleaning compound engineered to target specific contaminants without compromising pipeline metallurgy or operational safety. Furthermore, all chemicals are oil-soluble, and the generated waste is recyclable, which reduces costs for the operator.

N2 Solutions' chemical cleaning offering is a strategic extension of its long-standing expertise in pipeline integrity. The service line complements N2 Solutions' robust array of existing services, including:

· Nitrogen pumping, purging, transport, and storage

· Pipe freezing

· Pig tracking

· New, exclusive partnership with Arculus Solutions, featuring a breakthrough SputteredPipe™ technology that mitigates internal pipeline corrosion.

With over two decades of experience spanning the energy, LNG, and petrochemical sectors, N2 Solutions is uniquely positioned to deliver a wide range of integrity solutions that enhance pipeline inspection readiness, boost efficiency, and mitigate risk. These services are supported by 24/7 field responsiveness and real-time project execution, ensuring seamless integration and operational efficiency.

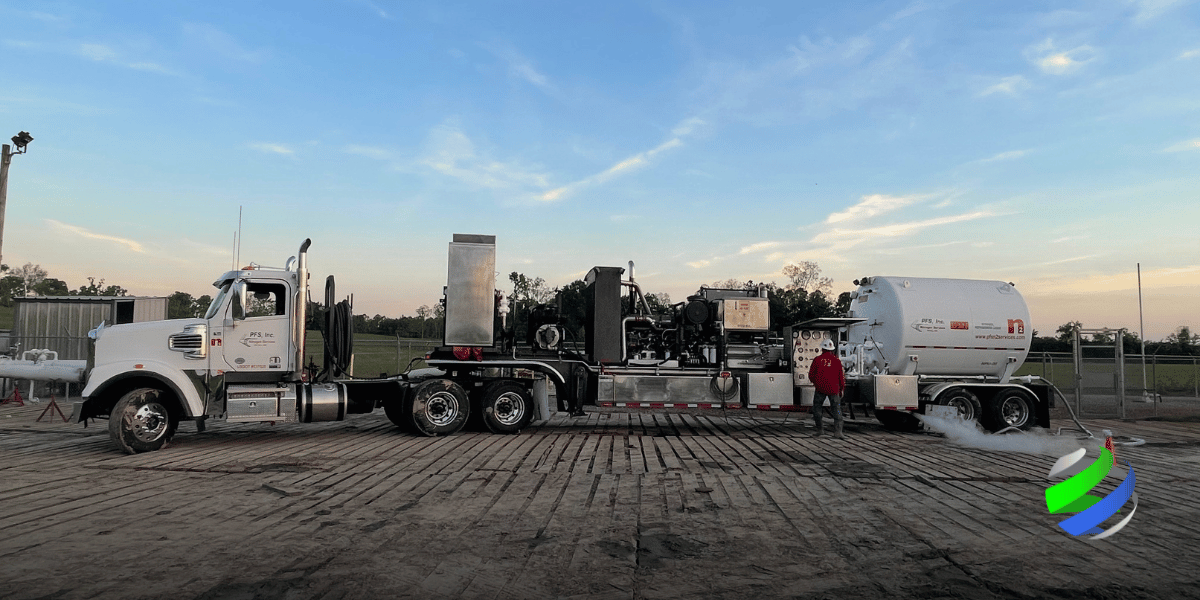

%20(3).png?width=180&height=90&name=N2%20-(300%20x%20150)%20(3).png) N2 Solutions strengthens their position as a nitrogen services leader with the acquisition of PFS Nitrogen Services, expanding its locations and product offerings. With pump trucks, nitrogen transports, pig tracking, ILI tool runs, and pipe freeze technology, N2 delivers cost-effective solutions to energy, industrial, chemical, and pipeline clients. Together, N2 Solutions and PFS set a new standard of excellence in nitrogen solutions for their customers.

N2 Solutions strengthens their position as a nitrogen services leader with the acquisition of PFS Nitrogen Services, expanding its locations and product offerings. With pump trucks, nitrogen transports, pig tracking, ILI tool runs, and pipe freeze technology, N2 delivers cost-effective solutions to energy, industrial, chemical, and pipeline clients. Together, N2 Solutions and PFS set a new standard of excellence in nitrogen solutions for their customers.

In the pipeline industry, maintaining the cleanliness and integrity of pipelines is crucial for ensuring safe and efficient operations. One of the...

When it comes to industrial pipeline services, safety, reliability, and performance aren’t just priorities — they’re non-negotiable. At N2...

When it comes to managing and maintaining pipelines, few names stand out like Pipeline Freezing Services (PFS), a sister company of N2 Solutions....