Pipeline Cleaning Products

N2 Solutions delivers chemical cleaning products that can be custom-formulated to combat contaminants, including black powder, iron sulfide, compressor oils, paraffins, microorganisms, salt, sand, and dirt.

Explore our range of specialty chemicals, engineered to boost system productivity and safeguard operational efficiency.

- Corrosion Inhibitors

- Defoamers

- Packer Fluids

- Pipeline Cleaners

- Solvents & Scale Removal

- Wax Dispersants

Corrosion Inhibitors

Formulated to protect pipeline infrastructure by creating a durable film on metal surfaces, reducing corrosion, and preserving the integrity of carbon steel systems.

Defoamers

Designed to suppress foam generated during pigging or fluid movement, these formulations control turbulence-induced foaming to maintain proper chemical flow and system stability.

Packer Fluids

Engineered to protect pipeline internals and idle sections, these fluids provide barrier protection against corrosion and microbial activity while maintaining uniform coverage in stagnant or low-flow areas.

Pipeline Cleaners

Advanced cleaning formulations that disperse solids, paraffin, hydrocarbon sludge, and iron-based deposits. These chemistries improve deposit removal, support pigging efficiency, and restore flow in pipelines and flowlines.

Solvents & Scale Removal

High-performance solvents that dissolve and disperse heavy organic and mineral deposits, including wax, asphaltenes, hydrocarbon sludge, and mud, for efficient removal during pigging or flush operations.

Wax Dispersants

Specialized dispersants engineered to break down and suspend wax deposits in pipelines and production systems, improving flow and pigging efficiency while preventing re-deposition.

Formulated for Your Pipeline Needs

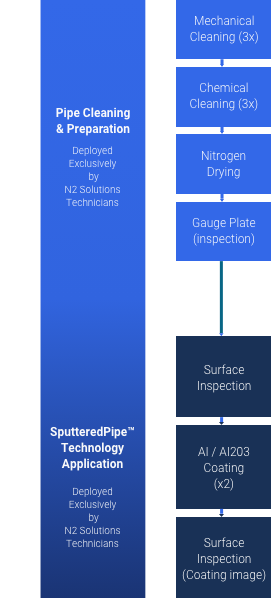

N2 Solutions' Pipeline Chemical Cleaning begins with lab analysis of sample debris present in your pipeline. From there, we formulate a custom cleaning solution engineered to clean effectively without compromising pipeline safety.

Our recyclable, oil-soluble formulations also reduce costs and environmental impact.

Why Pipelines Need More Than Mechanical Cleaning

High-pressure pipelines accumulate contaminants like:

- Black Powder

- Compressor Oils

- Iron Sulfide

- Microorganisms

- Paraffins

- Salt, Sand, Dirt, or Scale

Left untreated, these contaminants can:

Increase operating pressures needed to achieve the same throughput.

which decreases overall line productivity.

Increase downtime

which also increases cost for the operator.

Mechanical pigging dislodges deposits but also redistributes or breaks down solids, rather than removing them, which can still interfere with inspection accuracy.

N2 Solutions' chemical cleaning programs go beyond mechanical removal to break down and suspend contaminants, leaving pipelines cleaner, safer, and ILI-ready.